As another successful case of strategic cooperation with German company AFT, the automatic marriage system for the assembly of car body with the chassis parts in DPCA CP4 Chengdu was finished with commissioning successfully and put in operation by end of Aug.

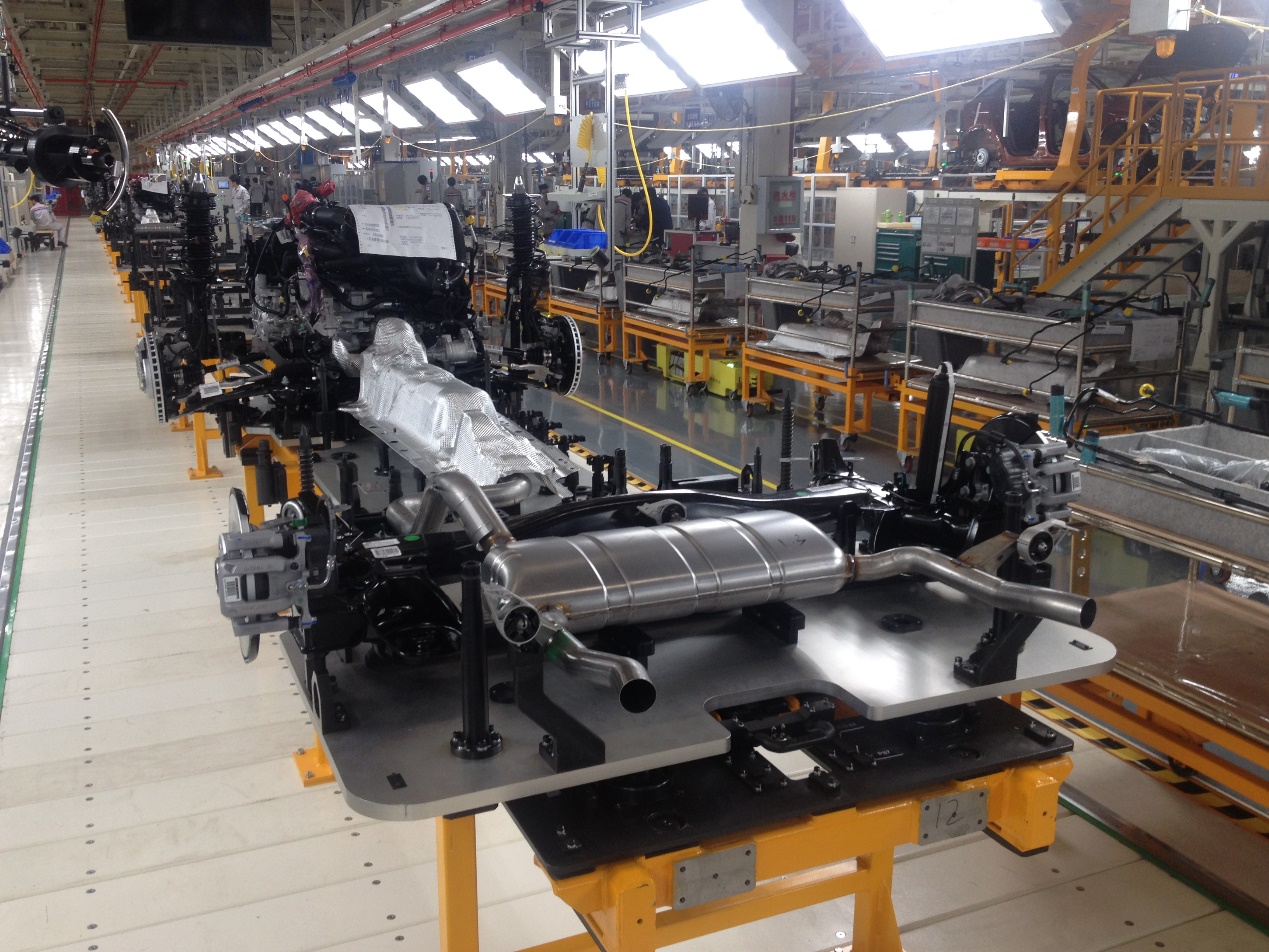

In DPCA CP4 Chengdu new final assembly shop project, Wuhan Boray is responsible for the turn-key supply to the automatic marriage line, chassis assembly POM line and marriage pallets, and also the electrical control system of body main assembly MV1 and MV2 lines including hardware and software design, control cabinet manufacturing, site installation and commissioning. Because the automatic marriage system is the first time application in Dongfeng group, and it is also highly concerned by the top management since this new technique is treated as a bright spot in this new plant construction, Wuhan Boray feels strong responsibility for this project.

The production cycle time in DPCA CP4 is 64JPH, and it is very difficult to achieve such a high production rate in fully automatic marriage process from the technique point of view, which requires that the settings of marriage process, the operation efficiency of marriage station equipment, the manufacturing tolerance of marriage pallets, the repeating accuracy for the positioning of car body with hanger in marriage station, and the quality of product itself, the combination of all these factors whether can achieve a perfect status so as to guarantee the success of the automatic marriage. With respect to the entire solution of a fully automatic marriage process and especially the design of marriage pallet, Wuhan Boray has taken great advantage of its expertise in vehicle marriage assembly and extensive experiences from previous projects, thus the system is ensured with a one-time success for the commissioning.

Make persistent efforts, Wuhan Boray!